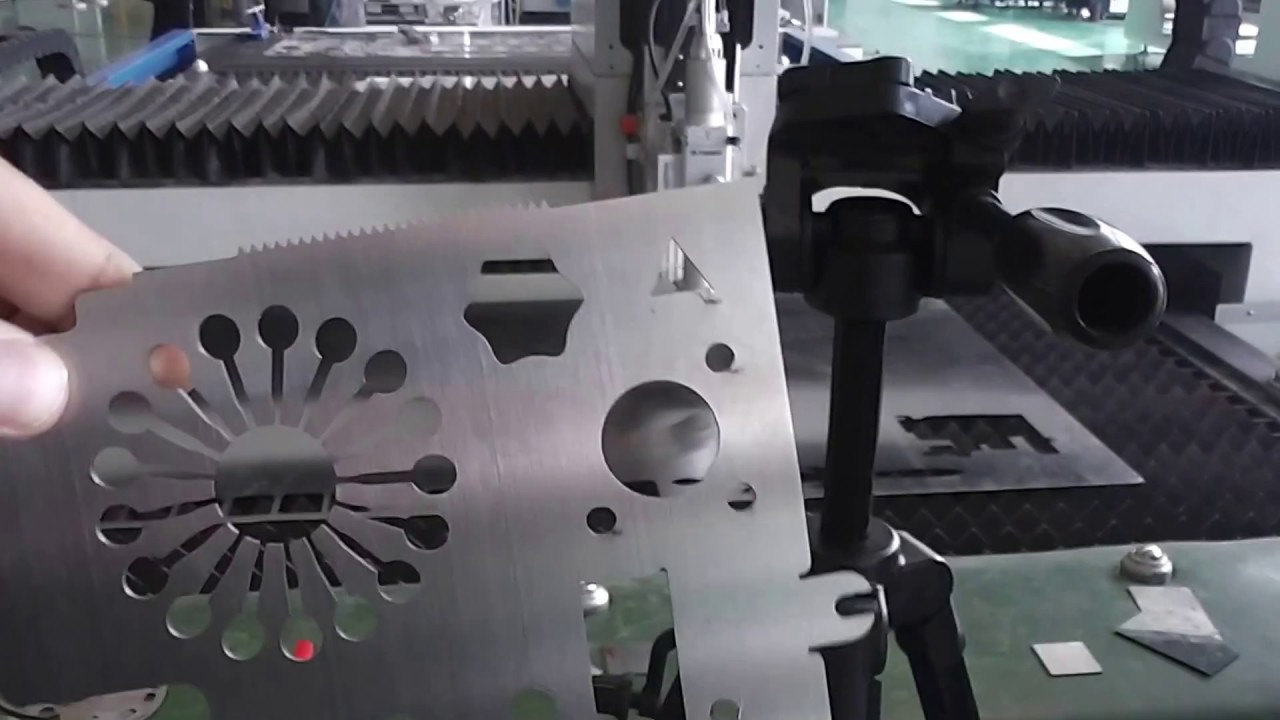

Looking for Metal laser cutting? It takes great precision and accuracy to achieve excellent results when working with sheet metal, whether it’s for heat exchangers, bespoke light fixtures, or ornamental architectural elements, among other things.

Metal laser cutting systems are essential tools for sheet metal companies that specialize in intricate tasks on a wide range of metals and thicknesses, such as sheet metal fabrication.

An effective laser cutting system may improve the accuracy, speed, and overall quality of the output if it is used correctly. Using this degree of technology, in addition to the advantages listed above, may enhance the diversity and specialty of the items you produce.

No matter what kind of sheet metal fabrication the client requires, you will be able to provide them with professional-quality solutions.

Higher Production:

Laser punching cutting systems produce bespoke metal components at a faster and more accurate rate, resulting in increased productivity and a more efficient workplace. One advantage of utilizing a machine with twin pallets is that employees may multitask while operating the laser on one pallet while unloading and reloading parts and supplies on the other.

It is also possible to increase productivity with laser systems that include features that can detect and fix faults before they occur. This is because more precise components are produced, and mistakes are kept to an absolute minimum.

Results of High Quality:

Thanks to the fine precision and pinpoint accuracy provided by modern metal laser cutting systems, you can offer your clients high-quality, intricate, and detailed results. Your finished goods will be more secure in their fit, and if the component you are working on is a substitute piece, it will be more compatible with the materials that are already in use. It is possible to adjust the laser’s power, which allows for more consistent results, while improved pulsing methods guarantee smoother edges.

Safety considerations:

When working closely with strong lasers for sheet metal production, safety should be the first and most important consideration. Fume blowers, which expel gases from the laser punching and cutting area, automated lubrication systems, as well as safety lights and mats are all possible safety elements of a laser cutting system.

Ensure that all users and employees are properly educated on the correct and safe use of the sophisticated metal laser cutting machine, as well as on how to perform necessary maintenance to keep the equipment operating smoothly and safely before bringing it into your business. For more information visit our Website